Let us bring water treatment expertise to your fingertips.

At Aqua Pure Technologies, we leverage cutting-edge technology and forward-thinking solutions to provide total water treatment services. As custodians of one of the Earth’s most essential resources, we adopt a comprehensive and sustainable approach to deliver effective, affordable, and long-term solutions for our clients.

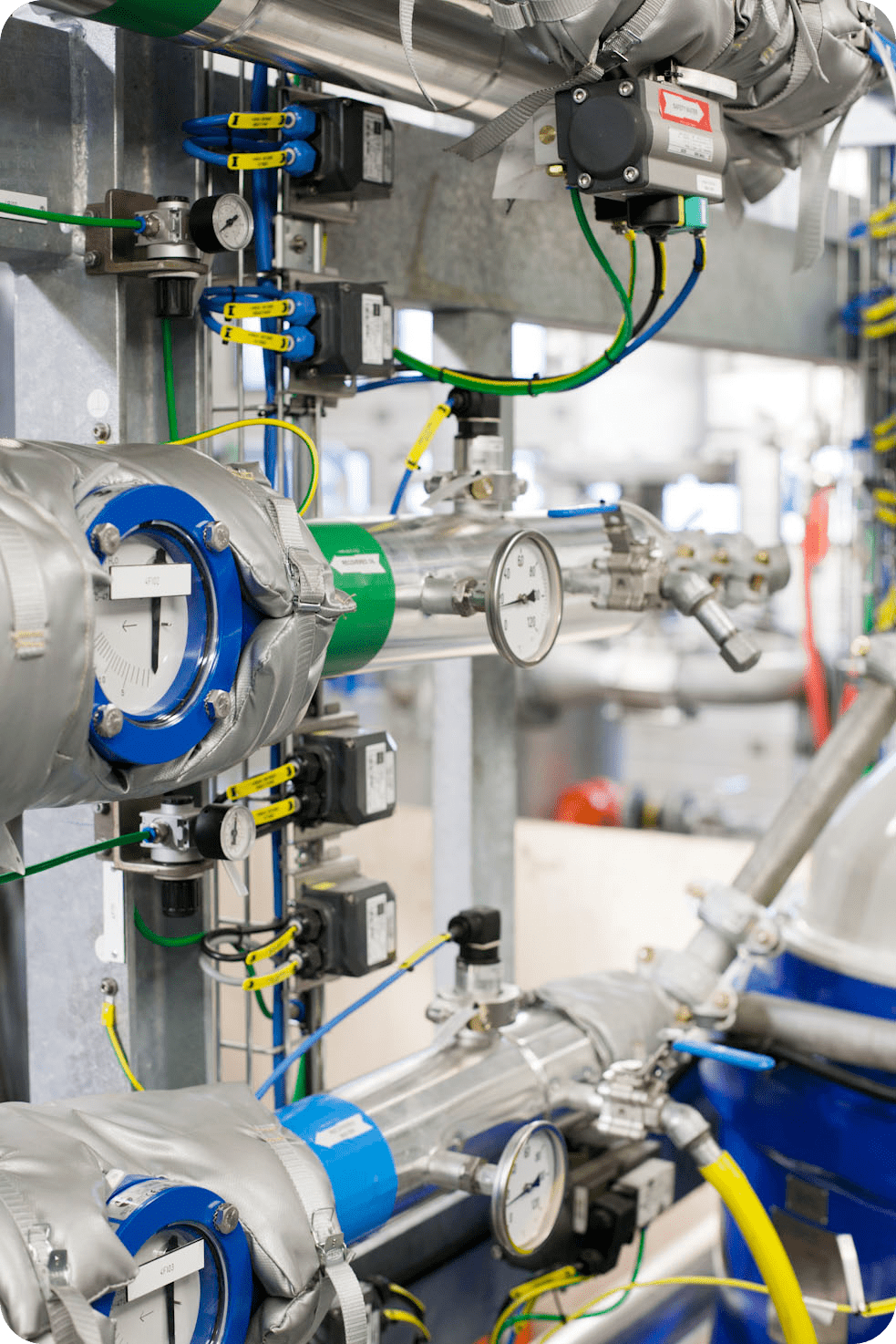

Cutting Edge Technologies

Chemical Treatment Solutions

We provide chemical pre-treatment products and filter aid chemicals, offering expert solutions for hazardous wastewater management and environmental sustainability. Our tailored solutions seamlessly integrate into industrial wastewater treatment systems, supporting processes such as sludge dewatering, pH neutralization and adjustment, solids settling and clarification, filter aid media, defoaming, and odor control.

Our company delivers reliable and cost-effective chemicals and consumables to ensure superior water quality for our clients. Our offerings include:

-

Anti-scalants – Enhancing operational efficiency by mitigating scale buildup and membrane fouling.

-

Biocides – Managing biofilm development to prevent hydraulic resistance, membrane deterioration, and permeate contamination.

-

Cleaners – Effectively removing various deposits from membrane systems.

-

Precipitants, flocculants, and coagulants – Specifically formulated for the metal industry.

By integrating our chemical treatment solutions, businesses can improve wastewater management, minimize environmental impact, and ensure compliance with industry regulations.

Reverse Osmosis

The system processes 750,000+ liters daily with automated real-time data monitoring. From plant upgrades to desalination and brackish water management, our membrane technology delivers a complete solution.

Electrocoagulation

Our (EC) destabilizes contaminants in water using electrical currents, aiding in separating oil, mud, dyes, and inks by breaking emulsions.

Hydrogen Sulphide (H2S Removal)

We offer complete H₂S Removal Methods with a combination of treatment methods that include; Chemical oxidation which converts H₂S for filtration, Aeration which exposes water to air for removal and Filtration that captures oxidized sulfur.

Ozone Treatment

Mitigates risks of contaminated water, ensuring compatibility with completion chemicals and protecting assets by:

-

Generating ozone, eliminating liquid biocides.

-

Managing iron and hydrogen sulfide.

-

Automatically adjusting dosage based on water quality.

-

Enhancing oil/water separation with ozone and oxygen injection.

Aeration - Efficient, Versatile & Easy

Our aerators maximize output with minimal energy, install quickly, retrofit easily, and ensure even aeration and odor control. Safe, Low-Maintenance & Reliable No moving parts mean less maintenance, enhanced safety, and remote monitoring. Built for durability, they perform in extreme conditions—no draining needed.

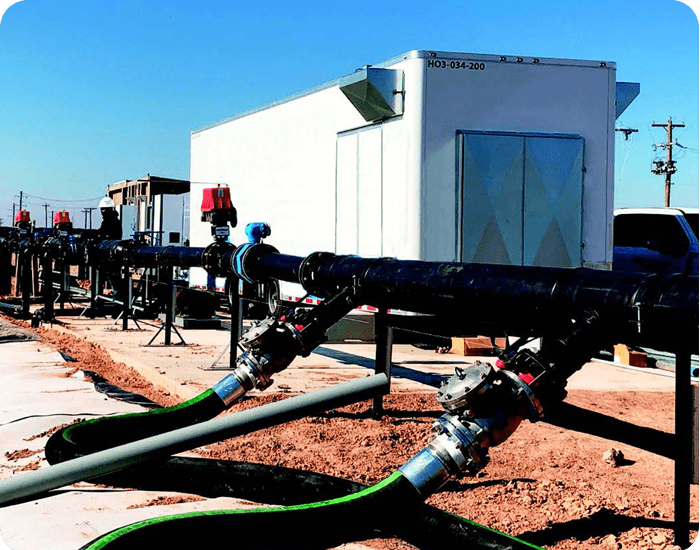

Mobile Hydrovac recycling systems

Efficiently recycles hydrovac slurry into reusable water and solid materials, reducing waste and conserving fresh water. It creates stable fill products and enables immediate reuse of refined water, making operations more cost-effective and environmentally friendly.

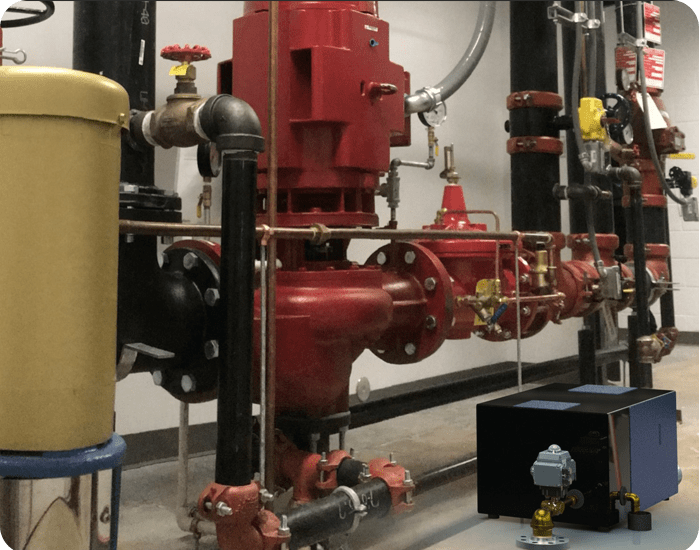

Solid Removal & Remediation

Solid Removal and Remediation provides mobile, in-situ waste separation using proprietary centrifugal dryer systems. Originally designed for oil-based drilling fluids, the technology was adapted in 2020 for hydrovac slurry. It processes slurry by removing gravel, drying materials to ~5% moisture, and recovering fine aggregates. Water is separated, treated, and flocculated for reuse by hydrovac trucks.

Electric Hot Stir tank System

The Electric Hotsir Tank System is an efficient and eco-friendly solution for fluid handling and storage. Designed with safety in mind, it features a three-compartment, 51 m³ tank with individual heat and agitation control. Its electric-powered system (480V, 3-phase, 100 AMP) ensures low operating costs and reduced environmental impact. A single control panel simplifies operation, while Camlock fittings and catwalk access enhance ease of use and maintenance.

In-situ water quality monitoring

Real-time metal detection: A sensor analyzes water every 5 minutes to measure metal concentrations, helping optimize treatment and protect the environment.

We provide reliable, turnkey water treatment solutions for industries and communities, ensuring compliance and offering expert guidance from assessment to implementation.

Industry Sector Applications

-

Oil and Gas (Produced Water, Frac Flowback, SAGD)

-

Mining

-

Municipal Wastewater

-

Pulp & Paper

-

Power Generation

-

Agricultural and Aggregation

-

Food & Beverage