In a world where water purity is critical, our Membrane Technology sets the standard for efficiency, reliability, and sustainability.

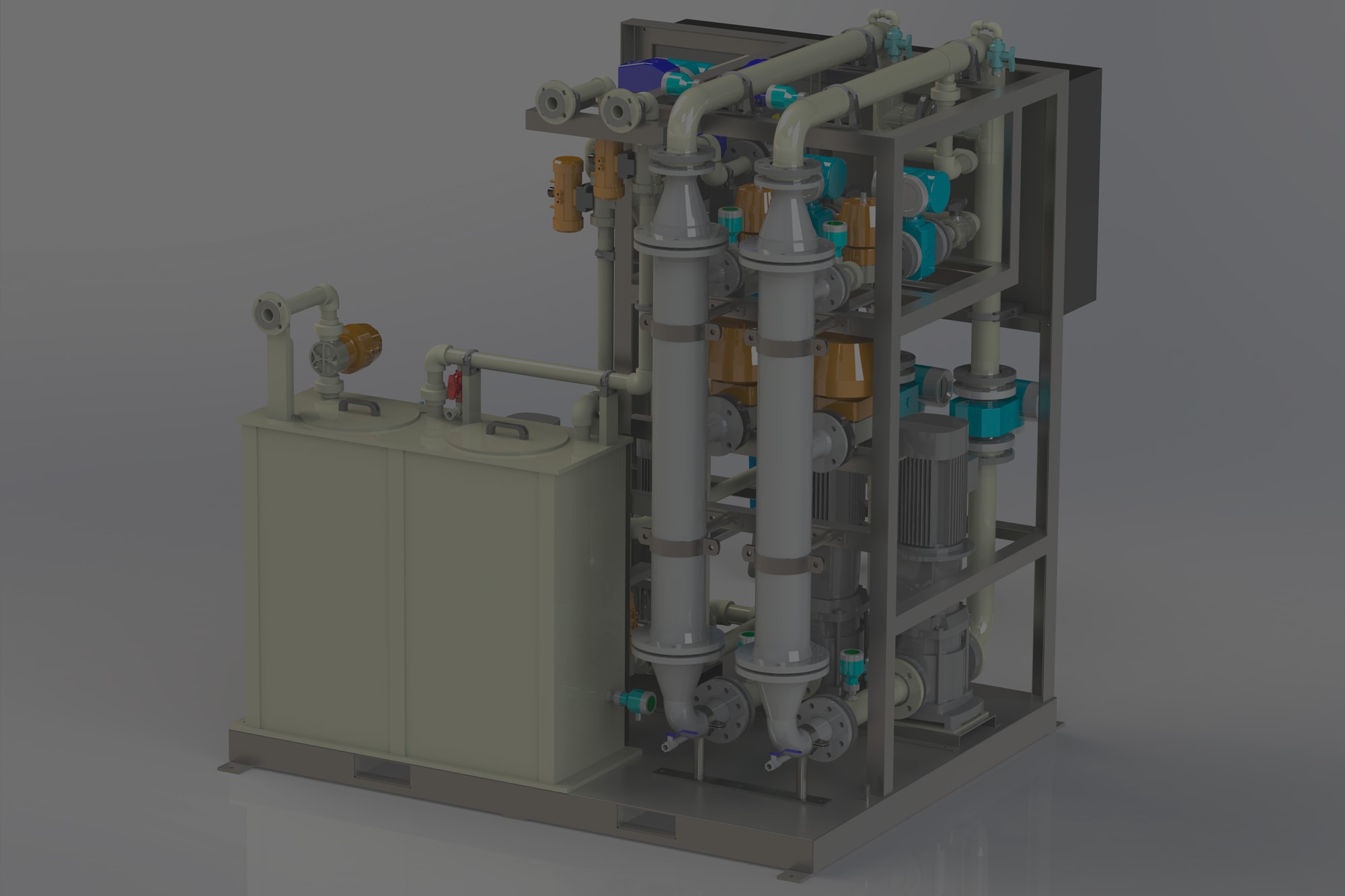

Advanced Membrane Filtration

The membrane technology allows PROH2O® to produce water with a TSS content < 1mg/L AND AN OIL CONTENT < 1 ppm. The membranes create a solid barrier that dispersed oil, solids and even bacteria will not be able to penetrate.

99.9%

Total suspended solids

99.9%

Bacteria

99.9%

Immiscible oil and fats

Endless Applications

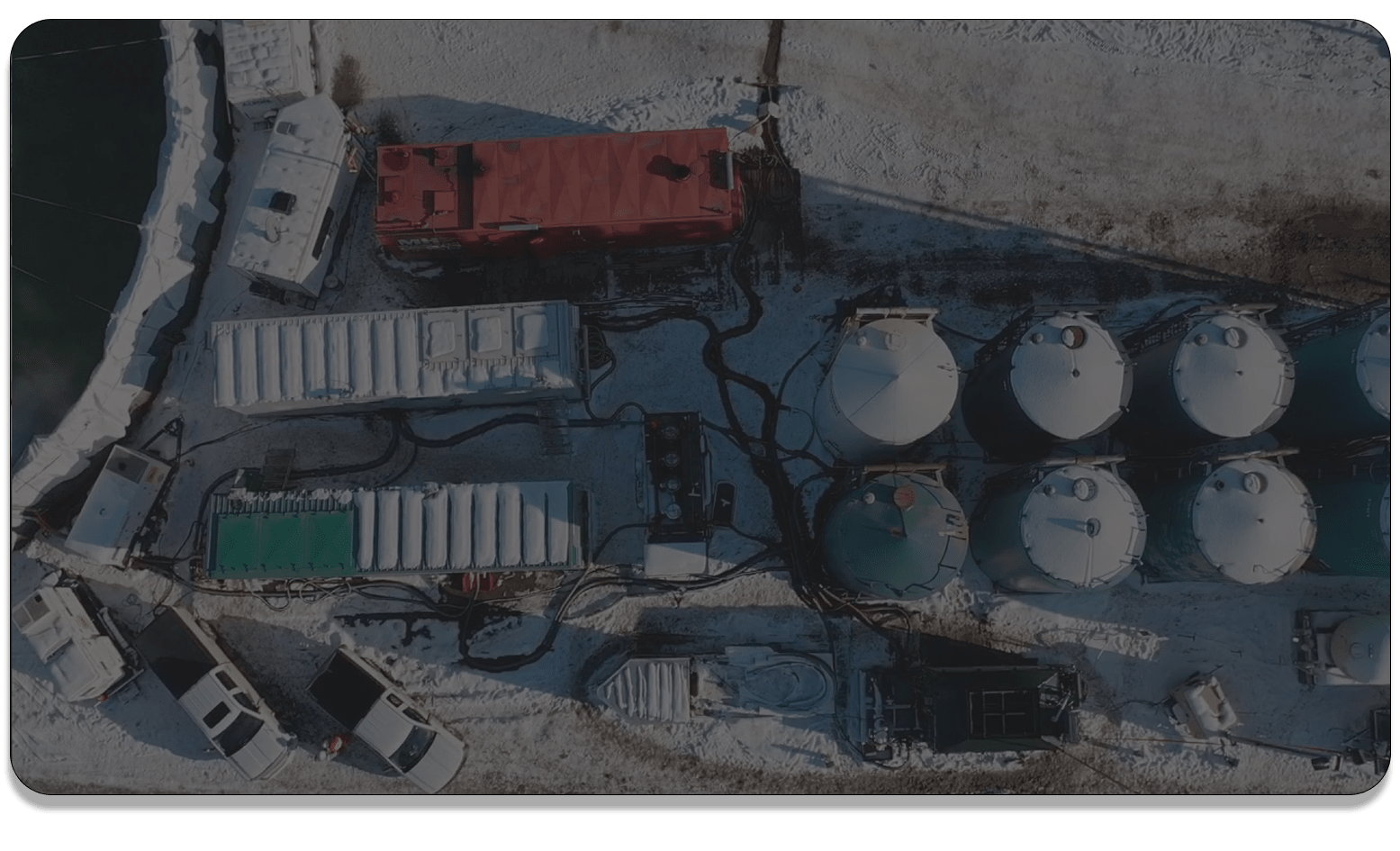

Fracturing Operations

Frac flowback and produced water recycling.

Wastewater Treatment

Providing cleaning, sanitation and water treatment solutions.

Enhanced oil recovery (EOR)

Safeguard resevoir integrity, improve performance and extend optimal lifespan.

Cleaning & Remediation

Reducing operational costs and environmental impact.

Disposal well Optimization

Extending the life of disposal wells and lowering costs.

Water Flooding

Optimizing resource recovery and minimizing waste for re-entry.

Industrial waste water polishing

Minimizing chemical use while ensuring eco-friendly and sustanable water treatment.

Operations

Sewage management and discharge solutions for all applications.

Our Membrane Technology sets the standard for efficiency, reliability, and sustainability.

Our patented PROH2O® Technology is engineered to remove 99.9% of all unwanted materials, including bacteria, suspended solids, oils, fats, grease, and turbidity, this cutting-edge solution ensures unparalleled water quality across industrial, refinery, and terminal applications.

-

Hybrid Membranes.

-

Highly Resistant to Mechanical, Thermal and Chemical Stresses.

-

High Porosity & Hydrophilic Surface.

-

High filtrate yield & Easily Backflushed.

-

Crossflow Filtration Minimizes Cake Fouling.

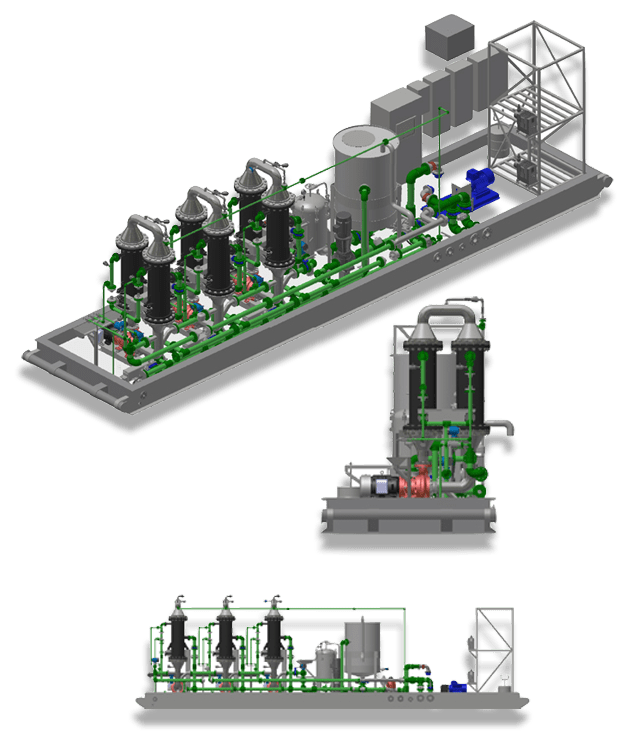

Volume Capacities

-

Trailer Unit: 400 L/Hr

-

2 Loop System: 60 m3/Hr

-

3 Loop System: 90 m3/Hr

-

4 Loop System: 140 m3/Hr

Technical Advantages

-

>95% Re-use of Effluent Water

-

99.9% Contaminant Removal

-

TSS, Oil & Grease, bacteria, color

-

Scalable to Any Capacity

-

Functional Life of +20 Years

-

Energy Efficient

-

Physical Separation Process

-

Chemical-free Process

-

PLC Automated System

-

Continuous Self-Cleaning

Large Scale Elimination

Suspended Solids & Turbidity

Particles, dirt, and silt.

Microorganisms

Bacteria, viruses, protozoa (like Giardia & Cryptosporidium).

Algae & Biofilms

Helps prevent biofouling.

Organic Matter

Including tannins, natural organic material (NOM), and some pesticides.

Colloidal Silica & Other Inorganics

Effective at removing fine particles.

Heavy Metals (Partially)

Removes metal particulates but not always dissolved heavy metals.

Some Proteins & Macromolecules

Common in industrial water treatment.

Oil and & Grease

With a residual waste stream of less than 1.5%, our system maximizes resource efficiency while minimizing environmental impact. Designed to operate across the full pH spectrum (0-14), it functions seamlessly without chemicals—though it can integrate with chemical treatments when needed.

Built for scalability and compliance with industry safety standards, our solutions range from fixed-in-place systems to fully automated units equipped with Clean-In-Place (CIP) technology, guaranteeing 99% uptime. Plus, our technology easily combines with other water treatment methods, optimizing water recovery and reducing waste.

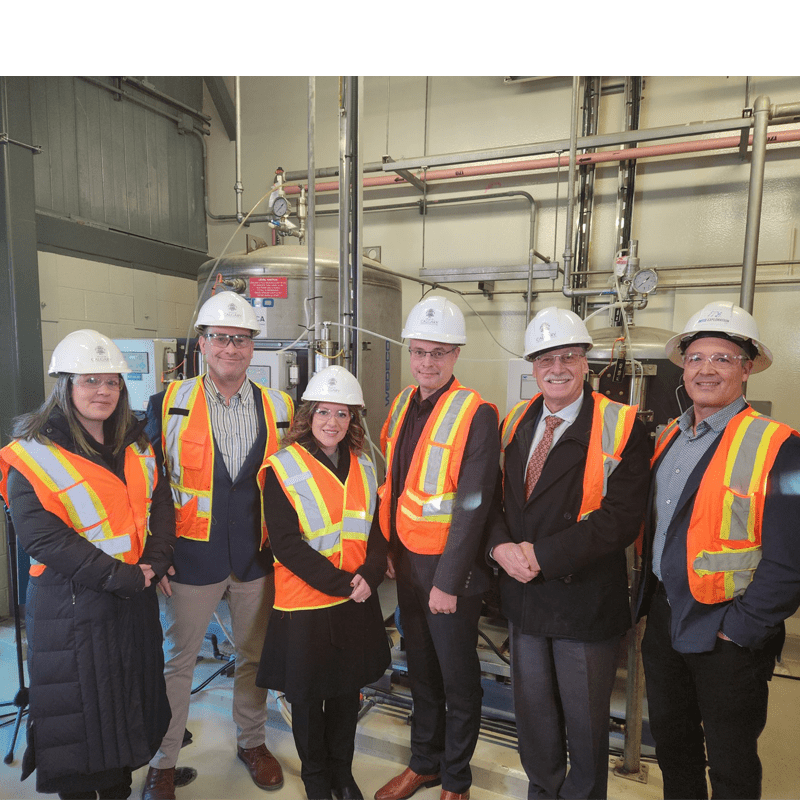

ERA Project Funding Announcement

“Sustainable Water Solutions for Enhanced Environmental Stewardship in Oil Fields”

Aqua Pure Technologies is exceptionally grateful for the support from Emissions Reduction Alberta (ERA), Alberta Innovates, Government of Alberta in addressing this significant issue and in fostering the creation of improved water treatment solutions for the technology and industrial sectors.